Expertise

Since 1998 STM supply as Tier 2 in automotive markets. We offer complex products and high volumes capability.

STM produce high-engineering products by turning, milling, drilling and grinding, designed by the customer or, alternatively, by in-house technical office.

We can offer in-house prototyping, sample productions, and PPAP, from low volumes products to high volumes product. We support the customer needs through all the steps needed to reach the SOP.

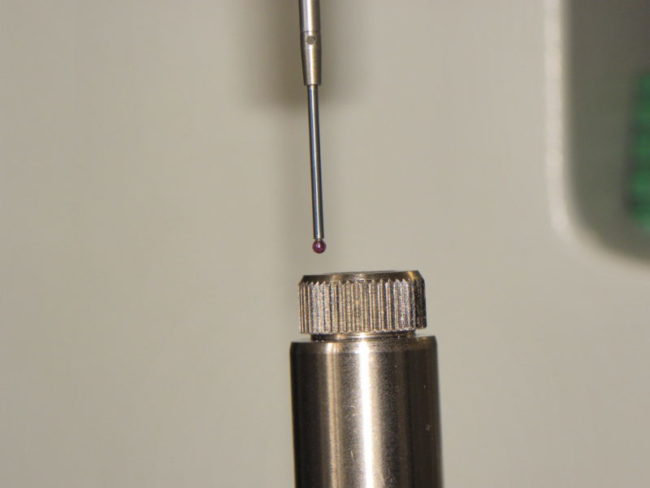

Our high quality standards could be performed through our in-house laboratory, at a controlled temperature. A wide variety of quality instrument support the production line to mantain high quality and reliable measurement. Our equipment range from profile projectors to pendulum, microscope, durometer, roughness, profilometer and many more in order to measure all the dimension we need in-house.

Our know how is center even on cleanliness level of our product, we can measure it through our cleanliness laboratory through test up to 10 µm filter – 300 µm max adm .length – 3mg max weight.

STM is able to offer support and solution for sustainable packaging and transportation. We manage returnable and non-returnable packaging, and according to customer need, consignment stock.

The technical office is composed of more than ten engineers and several software are used to design and analyze the customer’s drawing such as Tekla Structures and Cad-Cam. In fact once the drawings are received the engineers analyze each design details in order to industrialize the production.

The technical office of STM is the place where your products come to life. These can be projected by customer’s drawing or from the internal projecting and design. In fact, STM is able to offer customized solutions based on specific customer requirements.